After creating the cardboard version of our bag, we got our fabrics and began the process of making the actual bag.

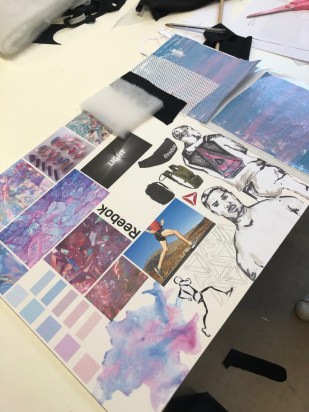

Before making the bag we had to create the screen prints which would be on the main bag to create the ombre, pastel finish. This part was mainly done by Aanya as it was in her department, textiles. Alice and myself helped her with mixing the colours, and washing everything up so the fabrics wouldn’t get dirty.

After several goes, we finally created enough screen prints on the fabric which would be the main bag and bum bag. Once the prints had dried we were all able to start cutting out the pattern pieces and putting them between PVC to create a waterproof material. Whilst the fashion and textile people were doing this, the product team were creating the metal pieces to create the logo and writing.

After cutting the pieces out we ironed the PVC together and began to sew the bag.

sewing the bag was quite challenging as the fabric wasn’t the easiest to sew through, especially when sewing the zips together.

Once we had sewn the main bag and bumbag one of us started to hand stitch the metal logo and writing onto the bag whilst the rest of us created the board for the presentation.

After several hours of sewing the bag together by myself and the other fashion members, we went onto creating the straps and adding the buckles to them. The straps were quite easy to create compared to the rest of the bag was the material was much more flexible, which is what we wanted.

Finally after finishing the straps the team added reflective strips to the front and that was the finishing touch to the bag.

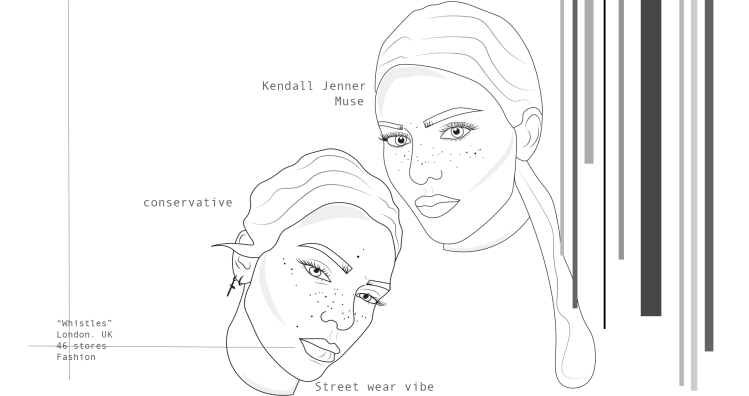

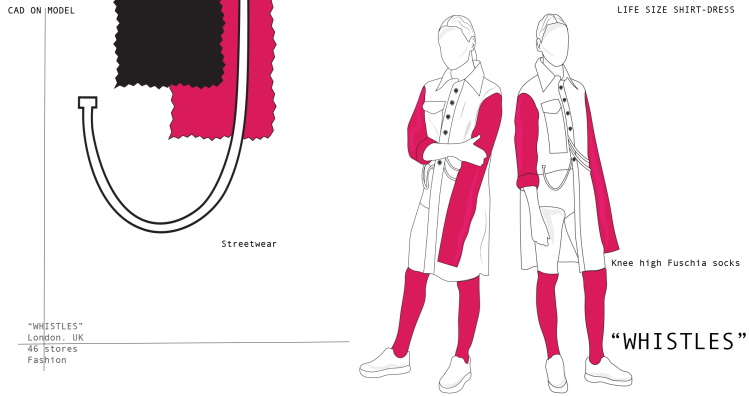

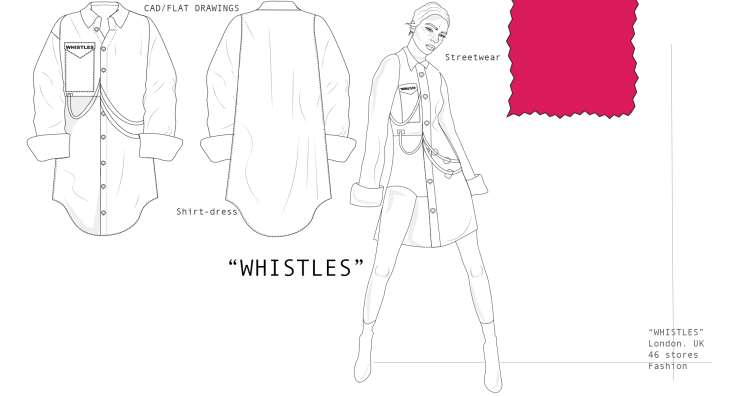

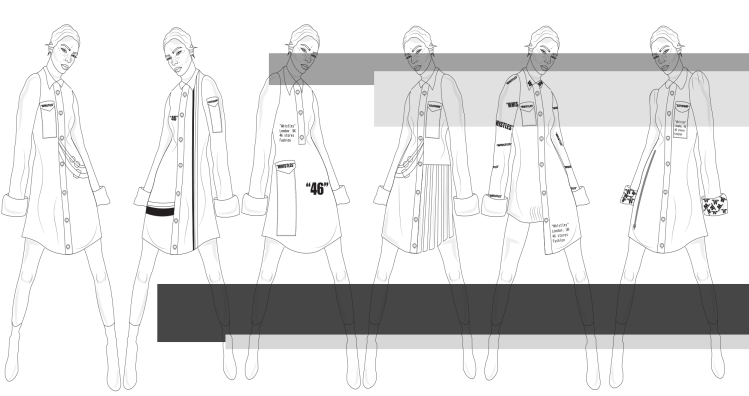

After developing my designs and research I started to create my Digital line up. For the line up I wanted to use the same silhouette shirt, whilst tweaking each design so each one had their own individuality. Again, looking at the line up you can see the inspiration from Off-White and the conservative look from Whistles which is what I wanted.

After developing my designs and research I started to create my Digital line up. For the line up I wanted to use the same silhouette shirt, whilst tweaking each design so each one had their own individuality. Again, looking at the line up you can see the inspiration from Off-White and the conservative look from Whistles which is what I wanted.